When selecting steel cable for control applications, purchasing managers face a difficult task: balancing performance, durability, and cost while ensuring the cable meets the mechanical and environmental demands of the system. Whether you’re sourcing for industrial automation, heavy equipment, or marine controls, the right cable can make the difference between seamless operation and costly downtime.

Here’s a breakdown of the key factors to consider when choosing the right steel cable for your control system:

1. Understand Steel Cable Construction

Steel cables are typically categorized by their strand and wire configuration. For example, 7×7 or 7×19. These numbers refer to the number of strands and wires per strand:

- 7×7: Offers moderate flexibility and strength. Ideal for push-pull controls and general-purpose applications.

- 7×19: More flexible, making it suitable for pulleys and systems requiring tight bends.

- 1×19: Very stiff, best for straight-line tension applications where minimal stretch is required.

Choosing the right construction depends on how much flexibility your system needs and how the cable will be routed.

2. Match the Material to the Environment

Steel cables come in various grades and coatings, each suited to different environments:

- Galvanized Steel: Economical and corrosion-resistant for indoor or dry environments.

- Stainless Steel (304 or 316): Offers superior corrosion resistance, ideal for marine, food-grade, or outdoor applications.

- Coated Cable (Nylon or PVC): Adds protection against abrasion and improves handling, especially in high-friction or exposed systems.

If your application involves moisture, chemicals, or salt exposure, stainless steel or coated options are often worth the investment.

3. Evaluate Load and Motion Requirements

Control cables must transmit force reliably, whether pulling, pushing, or both. Consider:

- Tensile Strength: Ensure the cable can handle the maximum expected load with a safety margin.

- Stretch Resistance: For precision control, low-stretch cables (like 1×19) are preferred.

- Flex Life: In applications with frequent movement, choose cables with high fatigue resistance and flexibility.

Also, factor in the type of motion; linear, rotary, or reciprocating, and whether the cable will be exposed to vibration or shock loads.

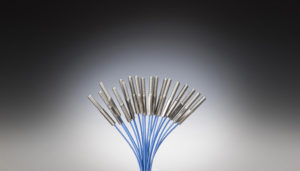

4. Consider End Fittings and Compatibility

The cable is only as good as its terminations. Ensure compatibility with your system’s hardware:

- Swaged Ends: Provide a permanent, high-strength connection.

- Threaded Terminals: Allow for adjustability and easy installation.

- Ball or Eye Fittings: Common in control levers and linkage systems.

Work with your supplier to ensure the fittings are properly matched to the cable diameter and application.

5. Don’t Overlook Compliance and Quality Standards

Depending on your industry, you may need to meet specific standards such as:

- RoHS or REACH compliance

- ISO or ASTM specifications

- FDA or NSF approval for food-grade applications

Always request documentation and testing data to verify that the cable meets your regulatory and performance requirements.

Picking Your Steel Cable

Choosing the right steel cable for control applications isn’t just about picking a size off the shelf, it’s about understanding the mechanical, environmental, and operational demands of your system. By considering construction, material, load requirements, and compliance, purchasing managers can make informed decisions that ensure safety, reliability, and long-term value.

Need help specifying the right cable? Our team of experts is ready to assist with application reviews, material selection, and custom cable solutions tailored to your needs.